How to determine the scrapping of a positive pressure air respirator? How to dispose of it after scrapping?

2022-11-23

The use of any product has a certain effective time. After a certain number of years, it may reduce or lose its function, and the positive pressure air respirator is no exception. During use, timely inspections should be conducted to avoid safety hazards.

At the same time, we must pay extra attention during use, so the inspection of the positive pressure air respirator during use is very important. So what are the scrapping standards and disposal methods for positive pressure air respirators? When does a positive pressure air respirator need to be scrapped, and how should we dispose of the scrapped air respirator?

1. Scrapping Standards for Positive Pressure Air Respirators

Generally, the service life of a positive pressure air respirator reaches 10-12 years. Due to material aging, corrosion, wear, and other reasons caused by long-term use of the components of the positive pressure air respirator, the overall technical performance will decline to varying degrees. When periodic technical inspections determine that it needs to be scrapped, the using unit can proceed with the scrapping process. For air respirators that are not used frequently, if they are determined to be in good condition after regular technical inspections, the service life can be appropriately extended, but it should not exceed 15 years.

If it is found that the positive pressure air respirator frequently malfunctions and cannot meet the relevant technical indicators after multiple repairs, or if it has been determined by a comprehensive technical department that the product needs to be replaced, it is recommended that the using unit scrap it in a timely manner to avoid affecting the health and safety of the users. In another situation, if the positive pressure air respirator is stored or used in a harsh environment, the using unit can appropriately shorten the service life of the positive pressure air respirator to better ensure that the air respirator effectively provides safety protection.

2. Disposal of Scrapped Positive Pressure Air Respirators

For positive pressure air respirators that have been scrapped, the using unit must take timely scrapping measures and cannot continue to use them to avoid safety hazards for staff. Scrapped positive pressure air respirators should be labeled and stored separately from other air respirators. The property owner should destroy or dispose of the scrapped positive pressure air respirators, or hand them over to the manufacturer of the empty positive pressure air respirators for disposal. Environmental protection laws should be followed, and they should not be discarded or disposed of in a way that harms the environment. When disposing, care should be taken not to allow scrapped parts to be reused improperly, which could pose risks to other protective measures.

3. So how can we properly maintain the air respirator to reduce wear and avoid premature scrapping?

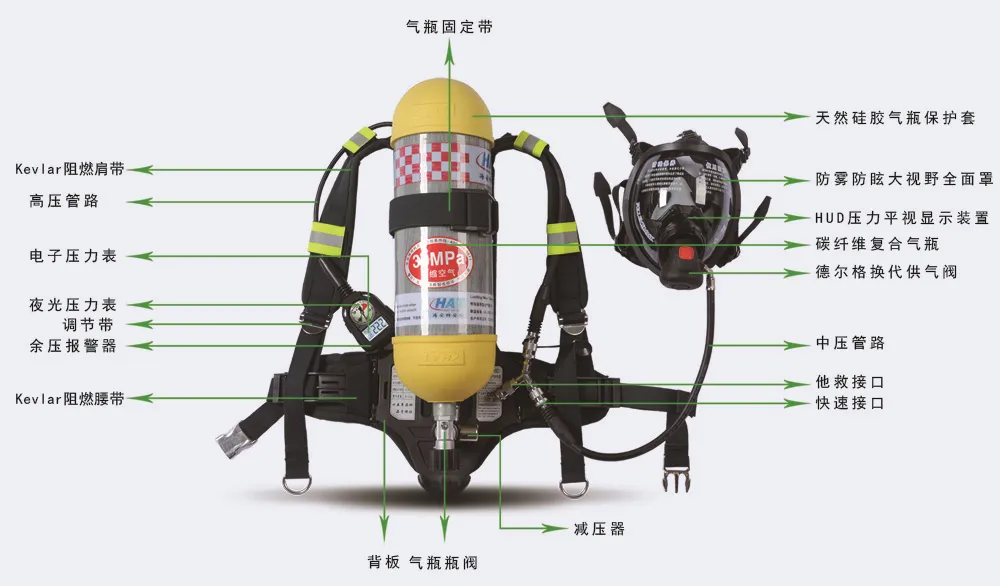

1. Face mask: Be careful of friction and impact with rough, hard materials to prevent scratching the face shield and affecting transparency and clarity, or even causing damage.

2. Shoulder straps and waist belts: When wearing, adjust the tightness as required, do not apply excessive force, and prevent damage from corrosive substances. Repair any damage promptly.

3. Air supply valve: After use, cover it with a dust protection cap to prevent debris from entering and causing blockage.

4. Back frame: Handle it gently during use to prevent collisions and friction with sharp objects that could cause damage. After each use, if it gets wet, take it to a dry, ventilated place to air dry, avoiding direct sunlight. When storing, ensure that all tightening straps are in the maximum position.

5. Pressure gauge: Checking the gas cylinder pressure is also a check on it. After checking, release any residual gas to ensure that the pressure gauge and hose are not damaged under prolonged pressure; also, do not use it to measure excessive pressure to avoid overload.

6. Gas cylinder: The gas cylinder is mainly used to store compressed air, and there are currently two types: steel and carbon fiber. When inflating, be careful: do not exceed the rated safety pressure, and the air humidity should not be too high, as it can lead to oxidation of the inner wall of the cylinder; during use, avoid violent collisions and friction with sharp objects, as this can lead to damage or even explosion; if necessary, make a protective cover for the gas cylinder to prevent friction damage. Steel cylinders should also be coated with anti-rust paint to avoid oxidation of the exterior; filled gas cylinders should not be exposed to direct sunlight or stored in high-temperature areas to avoid damage or explosion.

Key words:

Contact Us

Service Phone:

Contact E-mail:

Contact Address:

100 meters south of Chengnan Chenzhuang Junction, National Highway 220, Changqing District, Jinan City, Shandong Province

More information